An Architecture for Agile Assembly

Christoph Bergler, Andreas Best, Ben Brown, Zack Butler, Mike Chen, Mike Cozza, Mike Currie, Rich DeLuca, Mark Dzmura, Michael Ehrenstrasser, Marc Endress, Gregory Fries, Jay Gowdy, Alan Guisewite, Benjamin Hollis, Ralph Hollis, Jeremy Horner, Chip Jansen, Octavio Juarez-Espinosa, Sudhir Katta, Stephan Korner, Mark Kryder, John Kim, John Kozar, Shinji Kume, Michael Kummer, Joheun Lee, Dong Liu, Cornelius Niemeyer, Jimmy Ma, Will Milner, Patrick Muir, Arthur Quaid, Alfred Rizzi, Mahedev Satyanarayan, Constantine Scarvelis, Maria Sensi, Rob Schlender, Yuan (Amy) Sun, Johannes Vierheilig, Jeroen Vos, Yangsheng Xu , Stella Yu, and Garth Zeglin

|

Picture a modern disk drive.

|

The primary goal of the Agile Assembly Architecture (AAA) is to shorten the time to bring a complex, high-precision product such as a disk drive from the prototype phase to the production phase from months to weeks, or even days. The reduction of time to market is the main point of all agile manufacturing. AAA will help to achieve this goal by having:

|

|

|

|

AAA incorporates factory-wide standard procedures, protocols, and well-structured agent autonomy to simplify the process of designing and programming large high-precision assembly systems. AAA takes advantage of agents' self knowledge and ability to explore their environments to make the transition between simulation and reality as painless and seamless as possible.

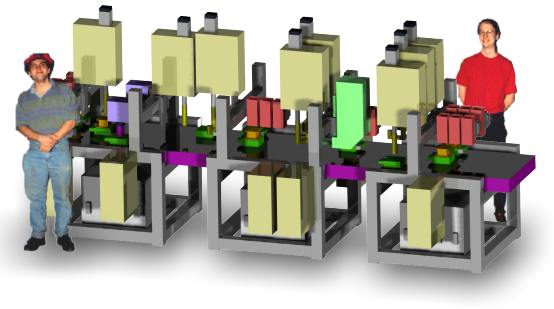

We are applying AAA specifically to tabletop-sized factories, or minifactories. The minifactories we are developing consist of modular elements such as high-precision platens, bridges for mounting modular robotic elements, precision 2-DOF manipulators, 2-DOF couriers, and parts feeders. Our prototypal application will be the assembly of high density "mechatronic" equipment.

For more information, please look at the following:

- A vision of the future

Pat and Chris try to get a product out the door! - Agile Assembly Architecture

A comprehensive framework for the design, programming, and deployment of agile assembly systems.- The annotated AAA life cycle

A description of how AAA is used to design, assemble, program, monitor, and change a complex assembly system. - AAA principles and philosophy

An overview. - AAA interface tool

The users' interface to the system. - AAA programming

Distributed programming of the AAA agents. - Automatic calibration

Generating a precise factory model from the actual factory.

- The annotated AAA life cycle

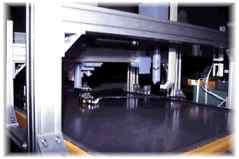

- Minifactory and its components

Descriptions, pictures, and movies of the elements that make up our minifactory.- Infrastructure

Base units, cables and connectors, bridges, and platen tiles: the passive components supporting minifactory. - Couriers

Moving products through the factory and cooperating in precision assembly operations. - Manipulators

Sensor-guided picking and placing of product parts. - Parts feeders

Delivering parts to manipulators. - Overhead processors

Special fastening and other operations.

- Infrastructure

- An AAA/minifactory example

Pictures, movies, and a VRML representation of a minifactory simulation building a product. - Some comparisons with other approaches

How AAA/minifactory compares to existing SCARA and planar motor precision assembly systems. - Popular articles about AAA/minifactory

A number of media articles about AAA have been published in several countries. - Frequently Asked Questions

E-mail your questions about AAA/minifactory. - Some links to agile manufacturing resources

Worldwide efforts to increase manufacturing responsivity. - Some links to related projects in precision assembly

Worldwide efforts in micro robotic manipulation and assembly.