Components of a Minifactory

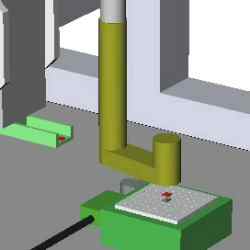

Perhaps the most striking departure from traditional automation systems and one of the most obvious embodiments of our philosophy of factory level integration can be seen in our choice to integrate product transfer and local manipulation. As such, we have eschewed the traditional use of SCARA manipulators coupled with part conveyor systems and local fixtures. Instead, we have two-degree-of-freedom (DOF) manipulators and two-DOF planar couriers moving over a high-precision platen surface. The couriers are responsible both for product transport within the factory and for transiently forming cooperative four-DOF manipulators when they presents sub-assemblies to a stationary manipulator.

Move your mouse over the rendering above (click on the image if your browser does not support rollovers) to see descriptions of fundamental minifactory components. Items in blue (base unit, bridge, platen, courier, manipulator, bulk parts feeder) are the main parts. Some details are shown in the smaller black lettering. The product sub-assembly is shown in orange, and parts are shown in red.

This approach to providing a four DOF assembly system has a number of advantages:

- Precision: Joint flexibility, link flexibility, sensor precision, etc. all limit the accuracy of serial linkage based systems. Our approach co-locates sensors and actuators to achieve about 100 times the precision of conventional assembly robots.

- Throughput: Couriers can proceed to different manipulators while the current one is picking a part and reparing for the arrival of a different courier.

- Floor space: The combination of a courier and manipulator occupies much less space than a conventional assembly robot for the same size product.

- Flexibility: Mechanical and electrical modularity allows easy integration of overhead processing elements ( e.g. screwdrivers, orbital head formers, glue dispensers, laser processors, etc.).

Here is a short movie showing parts placement. Motion has been slowed down to show detail. We have much more information available (descriptions, designs, simulations, and photos and movies of working hardware) for the fundamental minifactory components:

- Infrastructure

Base units, cables and connectors, bridges, and platen tiles: The passive components supporting minifactory. - Couriers

Moving products through the factory and cooperating in precision assembly operations. - Manipulators

Sensor-guided picking and placing of product parts. - Parts Feeders

Delivering parts to manipulators. - Overhead Processors

Special fastening and other operations.